Portfolio

Back

Design Alaska was the Mechanical and Electrical Designer-of-Record for this aircraft operations and 6-Bay hangar facility on Elmendorf AFB, Alaska. The project was completed fast-track design-build and administered by the US Army Corps of Engineers Alaska District.

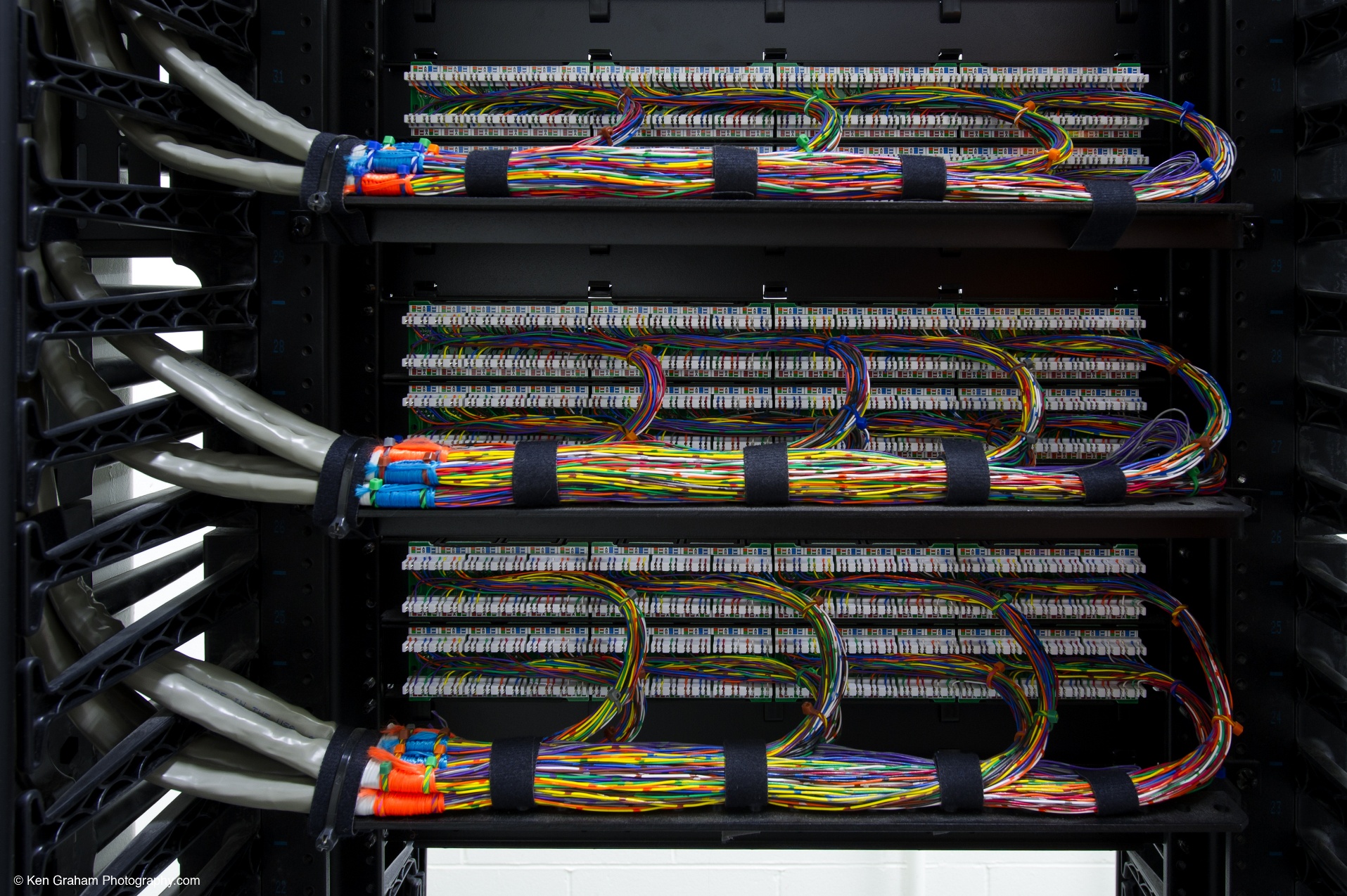

The 85,000 SF structure houses permanently assigned F-22A fighter aircraft and supporting aircraft maintenance and operations personnel. The project involved complex mechanical and electrical systems including high expansion foam fire suppression, oil/water separator systems capable of handling fuel spills, complex controls for multiple heating zones, snow melt heating systems, in-slab heating systems, multiple heat recovery systems, centrally controlled energy management system, specialized power system with device specific converters and receptacles, pop-up in-floor power receptacles, Class 1 Division 2 electrical systems, communications systems including highly secure network connections, and a large building service with multiple manual transfer switches to emergency back-up power.

The building, including Design Alaska’s mechanical and electrical engineering design work, was done in accordance with USGBC’s LEED Silver criteria and Energy Policy Act 2005 requirements. Design Alaska participated in development of the HVAC and electrical commissioning requirements and functional checks. The project was designed with Building Information Modeling (BIM) including the mechanical and electrical systems. This building is a high quality facility that houses are nation’s premiere fighting aircraft. We are very proud to have been a part of the project delivery team. The project is 100% complete and in use by the US Air Force.

. .

Design Alaska was the Mechanical and Electrical Designer-of-Record for this aircraft operations and 6-Bay hangar facility on Elmendorf AFB, Alaska. The project was completed fast-track design-build and administered by the US Army Corps of Engineers Alaska District.

The 85,000 SF structure houses permanently assigned F-22A fighter aircraft and supporting aircraft maintenance and operations personnel. The project involved complex mechanical and electrical systems including high expansion foam fire suppression, oil/water separator systems capable of handling fuel spills, complex controls for multiple heating zones, snow melt heating systems, in-slab heating systems, multiple heat recovery systems, centrally controlled energy management system, specialized power system with device specific converters and receptacles, pop-up in-floor power receptacles, Class 1 Division 2 electrical systems, communications systems including highly secure network connections, and a large building service with multiple manual transfer switches to emergency back-up power.

The building, including Design Alaska’s mechanical and electrical engineering design work, was done in accordance with USGBC’s LEED Silver criteria and Energy Policy Act 2005 requirements. Design Alaska participated in development of the HVAC and electrical commissioning requirements and functional checks. The project was designed with Building Information Modeling (BIM) including the mechanical and electrical systems. This building is a high quality facility that houses are nation’s premiere fighting aircraft. We are very proud to have been a part of the project delivery team. The project is 100% complete and in use by the US Air Force.

. .